Chapter 1

Survey

In this chapter we will discuss the general problems in

control design. In the first section

the environment for design with its confinements and

contradictory control aims will be

illustrated with a general blockscheme and an industrial

plant. In the second section the

main control design strategies of today will shortly

be characterized, their limitations and

benefits be indicated.

1.1 Control environment

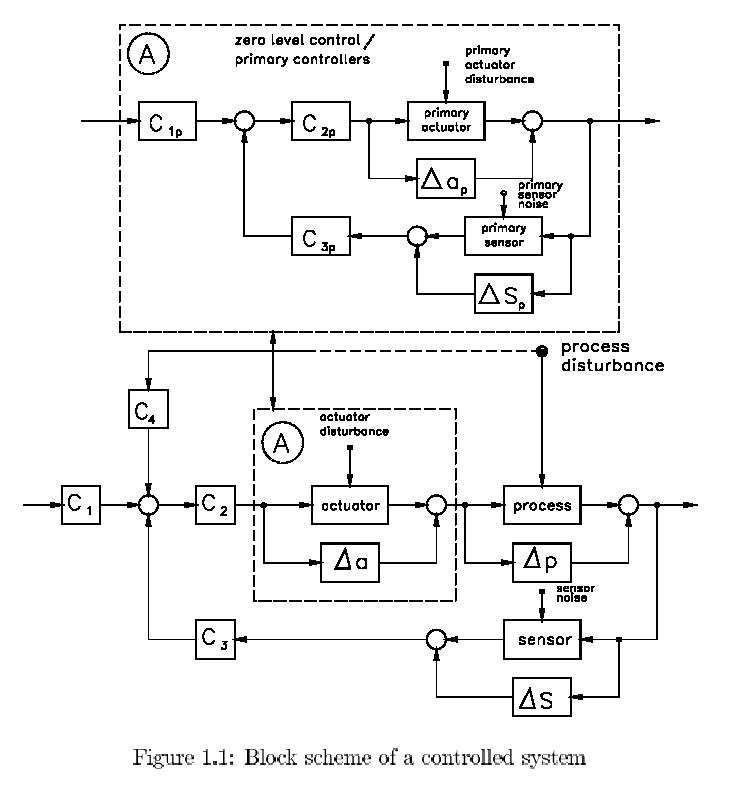

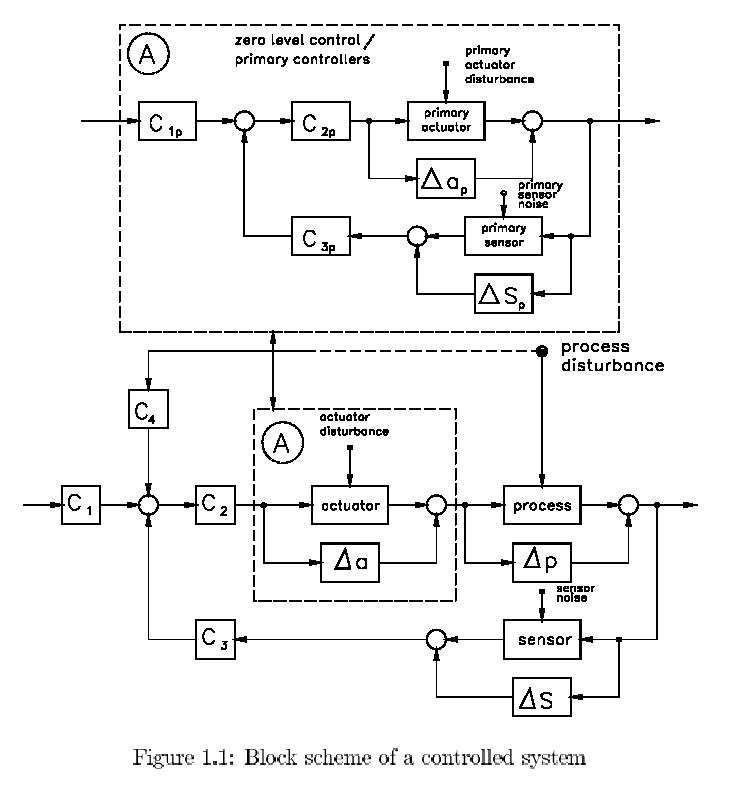

For facilitating the discussion consider a general and

rather complete representation of

a controlled system in Fig. 1.1. The nominal model transfer

function P of the plant to

be controlled is indicated by the block “process".

Because a model is always just an

approximation of the real world behavior Pt

we have to cope with a model uncertainty

block ΔP that bypasses the model such that:

Pt = P + ΔP

(1.1)

During operation the actual output y of the plant is

not only effected by controlled inputs

but also by process disturbances entering the process

at various points. Generally these

disturbance effects are combined in a disturbance signal

additive to the output.

The actual inputs of the plant

take the form of position, speed, force, torque, flow

of fluid, gas or heat, pressure and the kind, while the

output of the controller generally

is a voltage from e.g. the DA-converter. In between we

need an actuator that converts

the steering voltage into the proper quantity. This might

be a pump, a (servo-)motor, a

valve, a burner, a heat exchanger, etc. and these all

have in common that the effective

transfer is far from an ideal, static, linear function.

Most often, (primary) controllers

have been applied to let the closed loop transfer of

such actuators approximate a linear

transfer in a frequency band encompassing the dynamic

behaviour of the ultimate plant to

be controlled. Consequently what we show on the level

of the plant occurs as well on the

local level of the actuator which we have shown in Fig.

1.1 in the upper dashed block (A).

This actuator control is called `zero level control'

by means of `primary controllers'. On the

level of the plant we just consider a (closed loop) actuator

transfer model, its uncertainty

block _a and actuator disturbance analogously to the

plant itself. In most textbooks the

actuator is not explicitly visualized but tacitly enclosed

in the plant transfer.

What has been said about the

actuator applies to the sensor in a dual form. Actual

output quantities like position, speed, angle, rotation

speed, fluid level, pressure, tem-

perature etc. is to be converted to a voltage in the

proper range of the AD-converter.

Inevitably, the sensor transfer is not unity and we have

to deal with transfer uncertainty

and sensor noise. Sometimes primary controllers and noise

filters are used here as well to

improve the characteristics like in gyros, to control

the rotation speed, or in measuring

servo systems.

Finally we distinguish 4 blocks

Ci that constitute the control:

・ C1: a feedforward

block that filters the reference signal, indicating the aimed level

changes for the actual output.

・ C2: a compensator

block that adapts or corrects the actuator and plant transfer.

・ C3: a feedback

block that brings in the measured output signals.

・ C4: a possible

disturbance feedforward block. Sometimes disturbing quantities like

environmental temperature, pressure, humidity, grid voltage fluctuations,

light in-

tensities etc. can be measured and used to improve the disturbance reduction

by this

control loop.

These control blocks Ci have to be designed

such that the following goals and constraints

can be realized in some optimal form:

stability The closed loop system should be stable.

tracking The real output y should follow the reference

signal ref.

disturbance rejection The output y should be free

of the influences of the disturbances.

sensor noise rejection The noise introduced by

the sensor should not affect output y.

avoidance of actuator saturation The actuator

should not become saturated but has

to operate as a linear transfer.

robustness If the real dynamics of the process

change by an amount ΔP (and similarly

for the actuator and the sensor), the performance of the system, i.e. all

previous

desiderata, should not deteriorate to an unacceptable level. (In explicit

cases it may

be that only stability is considered.)

It will be clear that all above desiderata can only be

fulfilled to some extent. It will be

explained in chapter 2 how some put similar demands on

the controllers Ci, while others

require contradictory actions, and as a result the final

controller can only be a kind of a

compromise. To that purpose, it is important, that we

can quantify the various aims and

consequently weight each claim against the others.

As an example let us start with

the disturbance reduction and tracking aim. In order

to reduce the effect of the disturbance and minimize

the tracking error we can compare

the measured output with the reference by putting C1

= 1 and C3 = 1. Next a very

`large' C2 can then in principle minimize

the disturbance effects in the output to a very

low level. However, this very same high gained C2

has very unpleasant side effects : the

stability is endangered, the actuator will saturate and

the sensor noise will be introduced

and amplified to an unacceptable level. So these latter

three constraints define the bound

for the best obtainable performance in the sense of disturbance

reduction and tracking.

We can in principle relax the constraints by applying

actuators with a broader range and

sensors with less noise. This implies higher powered

and heavier actuators and higher

precision sensors that will certainly be more costly.

So, eventually, the economic principle

defines the ultimate compromise that follows.

Another example is that the

robustness requirement weakens the other attainments,

because a performance should not only hold for a very

specific process P, where the control

action can be tuned to very specifically, but also for

deviating dynamics in ΔP. There is

no way to avoid ΔP considering the origins of it:

unmodelled dynamics The nominal model P will often

be taken linear, time-invariant

and of low order. As a consequence the real behaviour is necessarily approximated

since real processes cannot be caught in those simple representations.

time variance Inevitably the real dynamics of

physical processes change in time. They

are susceptible to wear during aging (e.g. steel rollers), will be affected

by pollution

(e.g. catalysts) or undergo the influence of temperature (or pressure,

humidity … )

changes (e.g. day and night fluctuations in glass furnaces).

varying loads Dynamics can substantially change

if the load is altered: the mass and

the inertial moment of a robot arm is determined considerably by the load

unless

you are willing to pay for a very heavy robot that is also very costly

in operation.

manufacturing variance A prototype process may

be characterized very accurately,

this is of no help if the variance over the production series is high.

A low variance

production can turn to be immensely costly if one thinks e.g. of a CD-player:

in

principle one can produce a drive with tolerances in the micrometer-domain

but,

thanks to control, we can suffice with less.

limited identification Even if the real process

were linear and time-invariant, we still

have to measure or identify its characteristics and this cannot be done

without an

error. Measuring equipment and identification methods, using finite data

sets of

limited sampling rate, will inevitably be suffering from inaccuracies.

actuators & sensors What has been said about

the process can be attributed to actu-

ators and sensors as well that are part of the controlled system. One might

require

a minimum level of performance (e.g. stability) of the controlled system

in case of

e.g. sensor failure or actuator degradation.

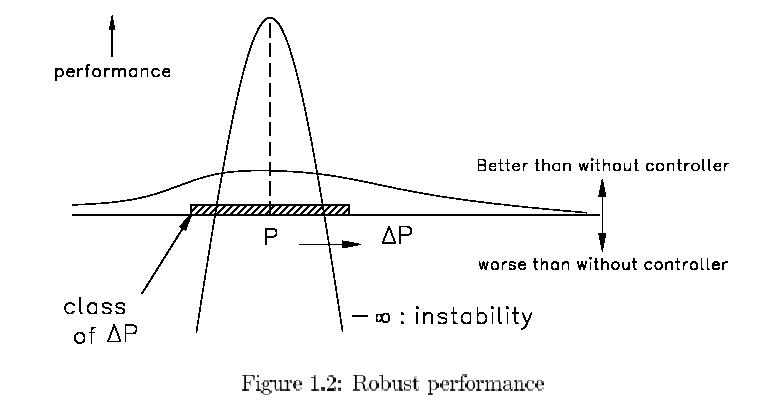

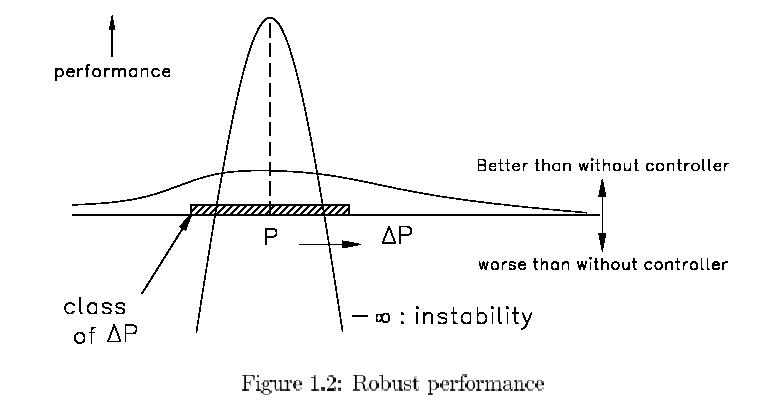

In Fig. 1.2 the effect of the robustness requirement

is illustrated. In concedance to the

natural inclination to consider something better if it

is higher, optimal performance is

a maximum here. So the vertical axis represents a performance

aspect; a higher value

indicates a better performance. Positive values are representing

improvements by the

control action and negative values denote a behaviour

worse than without a controller.

For extreme values -∞, the system is unstable. In this

super-simplified picture we let

the horizontal axis represent all possible process behaviours

centered around the nominal

process P with a deviation ΔP living in the shaded slice.

So this slice represents the class

of possible processes. If the controller is designed

to perform well for just the nominal

process, it can really be fine-tuned to it, but for a

small model error ΔP the performance

will soon deteriorate dramatically. We can improve this

effect by robustifying the control

and indeed improve the performance for greater ΔP but

unfortunately and inevitably at

the cost of the performance for the nominal model P.

One will readily recognize this

effect in many technical designs (cars, bikes, tools,

... ), but also e.g. in natural evolution

(animals, organs, ... ).

In above sketch of the environment

for control design we have tacitly assumed that all

blocks have only one input signal and one output signal

like in most of the conventional,

basic control textbooks. We then talk about SISO-systems

(Single Input Single Output).

For the general plants, to be discussed, the relevant

transfer may be multivariable resulting

in a MIMO (Multi Input Multi Output) transfer.

In the multivariable case all above single

lines then represent vectors of signals. For example,

in a CD-player the laser beam has to

be focussed on the track in the CD despite of the radial

and vertical unbalance caused by

the rotation. Because the radial and vertical disturbance

and control interact we really

deal with a MIMO-process. In stead of such a single product

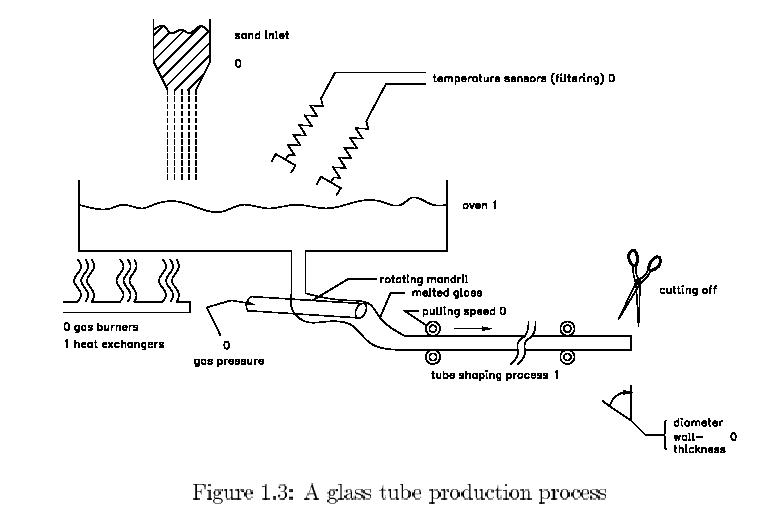

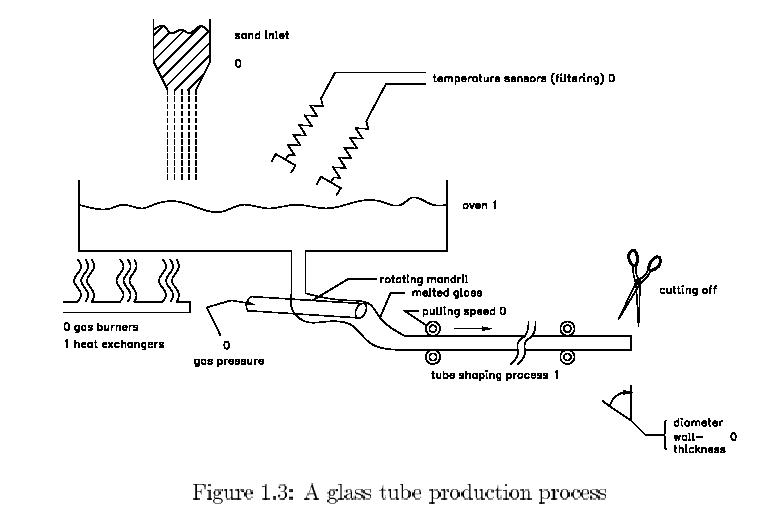

we would like to exemplify

control design categories by means of a production plant

as sketched in Fig.1.3. By this

production unit, glass tubes are manufactured for e.g.

fluorescent lamps. Immediately two

subprocesses can be distinguished on level 1 where we

reserved level zero for the implicit

actuator control. On the one hand we have the glass furnace

where the raw material sand

is transformed into a melted glass stream of the proper

viscosity. On the other hand we

have the tube shaping process where the glass flow is

moulded to a glass tube.

For the furnace, the control

inputs are the sand inflow, the gas flow to the burners,

the pressure of the cooling air and the outputs are the

melted glass outflow and its tem-

perature which directly determines its viscosity. Disturbances

on the outputs are caused

by fluctuations in the composition of the raw material

and the caloric value of the gas and

the air temperature.

The shaping of the tube is realized

by winching the steady glass flow on a rotating

mandrel under a certain tilting angle from which the

glass drains into what is called a

`ham'. This ham is kept under a certain pressure by the

gas that is pressed through the

hollow mandrel. The tube is then continuously pulled

from the ham and transported under

slow rotation over a length of about 60 meters for cooling.

At the end, the tube is cut into

pieces of proper length. The inputs of this shaping process

are the mandrel gas pressure

and the pulling speed. The outputs are the diameter and

wall thickness of the tube

measured at some distance from the ham because of the

extreme heat. As disturbances

can be mentioned the variations of the glass flow and

the viscosity (so the tracking errors of

the previous process), air temperature and pressure,

effects of the rotation of the mandrel

and the pulling machine (e.g. eccentricity of the wheels

and bearings).

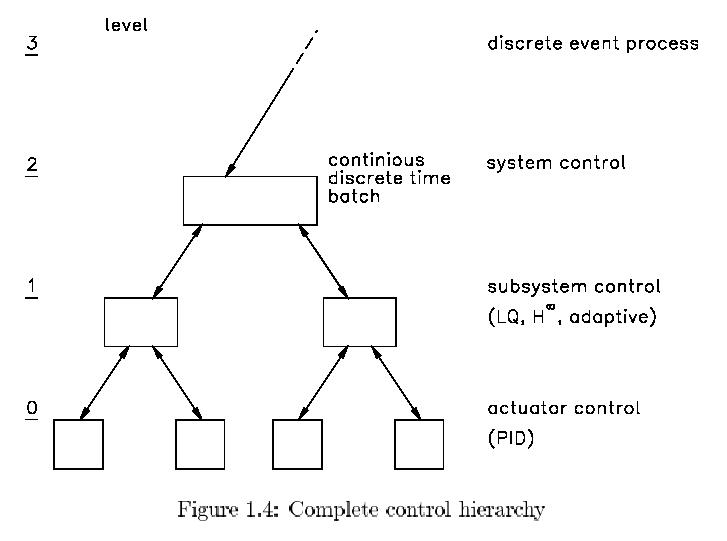

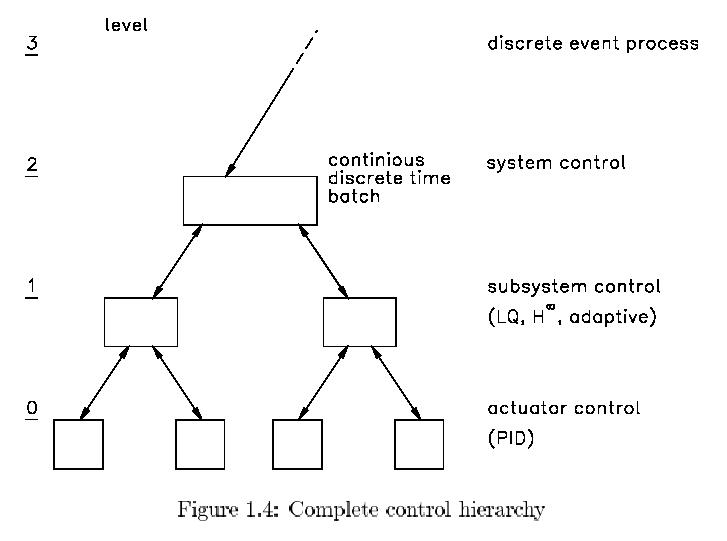

Let us explicitly discuss the control at several levels

now, as hinted at before and

illustrated in Fig. 1.4:

・ level 0: At zero level

the actuators and permanent conditioning processes are con-

trolled, like:

the actuators for the sand inlet , the gas pressure, the cooling air, the

mandrel gas

pressure, the pulling speed and the processes that keep the mandrel and

the tube itself

in constant rotation. This control is mostly done by the conventional

PID-controllers

or, in case of strong nonlinearities, by means of dedicated nonlinear

control techniques.

・ level 1: At level

one we distinguish the subprocesses with clear inputs and outputs

that depend on each

other, like here the furnace and the shaping process. Tradition-

ally the control

was done by operators but is gradually assisted or even taken over

by MIMO-control

techniques like LQG-control, adaptive control and robust control

to be discussed

in the next section.

・ level 2: On this level

the interaction between the various subprocesses is kept under

control by adapting

the reference signals. In principle the same techniques can be

used as for the

previous level but on a much slower time scale.

・ level 3 : Here the

inventory control of the raw material, the products in the form of

categories of tubes,

the gas supply, the costs of electricity is taken place. Completely

different techniques

are in use, like discrete event process control that will not be

discussed here.

・ level 4 : After some

time the furnace has to be rebuild because of degradation of

the walls. Also

the mandrel wears and the pulling machine needs servicing. This

time scheduling

and long term planning has time constants in the order of weeks to

months.

・ level 5 : At an even

lower pace runs the planning for the housing and product

selection for the

whole enterprise, where economic control is central.

By means of above hierarchy of

levels the problem of hierarchic control is easy to grasp.

The higher the level the lower the pace. Each lower level

acts more or less as an all pass

process for the frequency band of its upper level. There

is a command stream from above

that puts severe constraints on the lower level process

control by means of the reference

signals that can thus be rather low frequent. The control

at the higher levels is based upon

information from the lower level. But this lower level

proceeds at a much higher rate so

that there is much too high an information density unnecessary

for the higher level. An

appropriate information stream is therefore indispensable

which is balanced between the

data overload and information insufficiency. Both can

lead to low performance or even

instability.

So the real environment of control

design teaches us that we have to deal with multi-

variable systems, that control will be a compromise in

the fulfillment of contradictory aims

and constraints, that control performance has to be robust

for model perturbations and

that the systems might be embedded in an hierarchical

structure.

There is still another issue

that becomes evident from the example of the glass tube

production line. In the start up situation it will be

clear that we have to deal with a

substantially nonlinear process. The furnace has

to be heated up from zero and special

techniques are necessary to pull the initial tube from

the ham. A similar situation occurs

at the shut down procedure. Less pronounced, but nonetheless

nonlinear, is the behaviour

in the change over trajectory where the production is

changed from one diameter and wall

thickness to another set of these. The control of this

change

over is substantially different

from the control in a constant working point where indeed

a linear model with a linear

controller could do the job. So the issue is how to deal

with nonlinear plants. We list the

following approaches:

・ single linearisation.

If the signals just show small excursions about some average

value, the

obvious solution is to linearise the plant in the proper equilibrium or

working point.

The nonlinear effects are then supposed to remain relatively small

and can be

treated as model perturbations or considered as disturbances. This

way the linearised

plant can be controlled by classical PID-controllers or, if better

quantisised,

by robust control techniques.

・ multiple linearisation.

If the range is to big to be covered by a single lineari-

sation, it

can be partitioned into overlapping subranges for each of which a single

linearisation

can be developed. The overlapping is then necessary to switch from

the one linearisation

to the other. This switching should be taken very literal be-

cause the

model is changing and thus the necessary controller as well. So the one

controller

is switched o_ while the other is switched on. The problem then hides

in the initial

state of the controller that is switched on. It takes some time before

the transient

is died out or one has to `warm up' the controller before the switching

which requires

special techniques and puts constraints on the controller. On top of

that, one

has to make sure that the next moment the switching is not again reversed

so that a

kind of oscillation occurs. This is overcome by the mentioned overlap and

by a properly

defined switching hysteresis. Nevertheless, it appears to be difficult

to realize

a bumpless transition . As an alternative a "fuzzy" transition is proposed,

where the

output of the one controller is gradually diminished and overtaken by the

output of

the other controller. Consequently we have to deal with a weighted sum

of

both controllers

in parallel which effect is hard to analyse for e.g. stability. Finally

and again

one has to compromise between a fine meshed partitioning for the best

linearisation

and a minimum number of transition `bumps'.

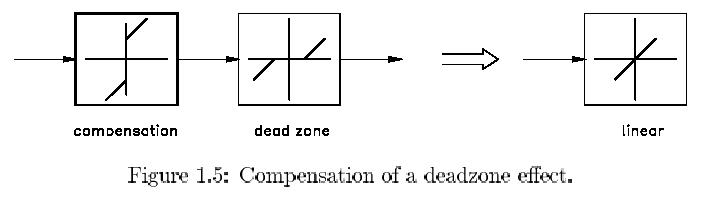

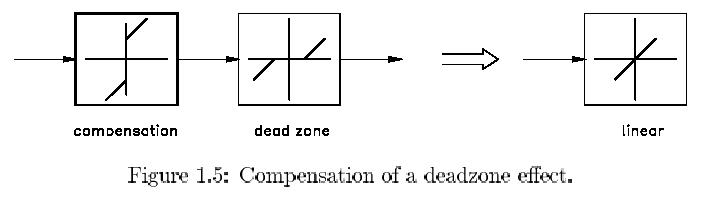

・ linearisation by compensation.

If the nonlinearity is essentially nondynamic it

can be compensated

by the static complementary function. As an example the dead

zone can be taken

as illustrated in Fig. 1.5 where the complementary function is

also shown. In this

way one can e.g. compensate for the nonlinear valve character-

istics, nonlinear

transmission rates, friction characteristics and also nonlinearstatic

measurements.

・ adaptive control In

the case that the plant dynamics are linear over limited time

horizon but

that they change over the long run, adaptive control can be applied.

During the

time span that the dynamics can be supposed to be linear and time

invariant,

the transfer function is estimated and a proper controller tuned for this

transfer.

This estimation and tuning is then continued on-line so that slow change

in time can

be followed.

・ linearisation by feedback.

Under certain complex conditions, that can be verified

if the plant

dynamics are not too complicated, the dynamics can be made linear

by means of

a nonlinear feedback. Not only for a limited range as for the single

linearisation,

but for the very range for which the nonlinear model holds true. It can

only be applied

if the model is very good and if sensor noise and disturbances can

be neglected

to a certain level. This can e.g. be true for mechanical systems like

robots.

・ nonlinear control

One can attack the nonlinear plants in their own nonlinear

domain by

dito controllers. Soon, if the plant is somewhat complex, this founders

on the very

complex computations.

・ `intelligent control'.

As the previous approach suffered from the complexity of the

analytical

computations, it is often tried nowadays to find the nonlinear dynamic

controller

by optimization within a set of nonlinear, dynamic transfers. This set

can be a neural

network or a fuzzy logic based controller. The techniques will be

discussed

in later sections but the main problem is in the choice of the controller

set

and in the

optimization: One never knows whether the set is big enough and the

optimization

can stop in a local extremum.

If the nonlinearity

has a `conditional' character expert systems can help. It will be

clear that

conventional PID controllers can do very little in case a sensor or actuator

breaks down.

However, an expert system can choose the proper strategy if it is well

designed.